Welcome to Diversified Rack & Shelving, Inc.

Diversified Rack & Shelving, Inc. has quickly become one of the largest buyers and sellers of industrial rack and shelving Nationwide. Ron and Diana Longo

In today’s fast-paced business environment, optimizing your warehouse or manufacturing space can significantly impact your operational efficiency and bottom line. Diversified Rack & Shelving offers top-notch computer-aided design (CAD) services to help you make the most of your warehouse space. Our expertise with computer-aided design software ensures that every square foot of your facility is utilized effectively, driving productivity and maximizing storage capabilities.

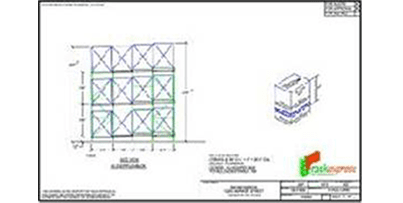

Our CAD engineering, layout, and design services in NJ, NY, & PA are designed to meet the unique needs of your business. Whether you need to redesign an existing layout or create a new one from scratch, our team of experts is here to help. We use cutting-edge CAD software to create detailed floor plan drawings, incorporating every element from rack locations to structural and seismic calculations. Keep reading to learn more about how our CAD engineering, layout, and design services in NJ, NY, & PA can transform your space, or reach out to us today to start your project!

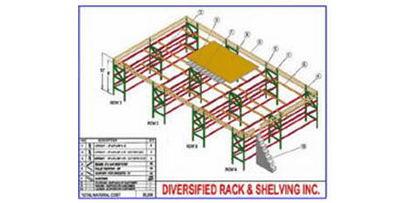

As industry experts, our engineers know firsthand that every warehouse is unique, which is why we offer customized CAD engineering, layout, and design services in NJ, NY, & PA to meet your specific needs. Our CAD designers use state-of-the-art software and tools, including technologies such as AutoDesk, to create precise, high-quality digital models based on the architecture and dimensions of your existing space. These plans include everything from bin shelving and mezzanines to conveyor systems and security cages, ensuring that every aspect of your warehouse is optimized for efficiency and productivity.

Before we begin drafting your design, our warehouse optimization process begins with a thorough field measurement of your warehouse space or manufacturing facility to verify layouts and elevations. We take into account any interferences or constraints that may affect the design, then import the data into our 3D CAD software to create a high-quality design.

As our CAD architects and engineers continue drafting, we work closely with you to review machine dimensions and other storage and retrieval features, minimizing aisle sizes and maximizing storage capacity. By leveraging our extensive knowledge of IBC codes and RMI regulations, we ensure that your warehouse layout complies with all relevant safety and structural standards across various industries. With over 20 years of experience with computer-aided warehouse optimization tasks, our seasoned system analysts are also well-versed in township codes and requirements for buildings throughout NJ, NY, and PA.

The benefits of our CAD warehouse layout projects for companies are numerous. Because Autodesk and other CAD software are used to create a highly detailed and accurate virtual scale model, users can visualize the final creation and discuss modification during the drafting stage — before changes are made to the physical space. This not only helps save time and money on materials and installation but also ensures that the final design is developed to incorporate all of your exact requirements. With our expertise and organizational capabilities, you can achieve an efficient warehouse layout that will power your business like never before!

Computer-aided design systems play a crucial role in modern warehouse layout planning. CAD software allows designers and engineers to create detailed and accurate representations of physical objects and dimensions. By creating geometry-accurate models, we ensure that every element of your warehouse or manufacturing facility’s layout is accurately represented.

One of the key advantages of our CAD engineering, layout, and design services in NJ, NY, & PA is the ability to modify and adjust designs quickly and easily. This flexibility is essential in warehouse layout planning, where changes are often necessary to accommodate new equipment, objects, or operational requirements. 3D CAD software allows us to make these adjustments without having to start from scratch, saving time and ensuring that the final design meets your needs. Additionally, this innovative design software enables us to create scale-accurate models that can be viewed on a computer or mobile device, providing a comprehensive view of the space and allowing users to visualize the final result.

CAD drafting is also invaluable for creating detailed documentation and drawings. These documents are essential tools for guiding installation and construction projects, ensuring every component is installed correctly and according to plan. Our CAD model drawings are created with all necessary features in mind, such as rack locations, elevations, and structural calculations, providing a clear and accurate model of the final layout. This level of detail helps prevent errors and ensure that the final product design meets users’ expectations.

"*" indicates required fields

In addition to our industry-leading CAD engineering, layout, and design services in NJ, NY, & PA, we’re also proud to specialize in…

Ready to transform your warehouse with expert CAD engineering, layout, and design services in NJ, NY, & PA? Reach out to Diversified Rack & Shelving to learn more about our CAD layout projects. Our experienced product design team is here to help you achieve the perfect warehouse layout created with your specific needs in mind. With our high-quality 3D CAD software tools and extensive industry knowledge, we can design storage systems that maximize your warehouse or manufacturing space, improve efficiency, and comply with all relevant codes and regulations. So what are you waiting for? Contact a designer today to learn about how the power of technology, geometry, and electronics can take your organization to the next level!

Diversified Rack & Shelving, Inc. has quickly become one of the largest buyers and sellers of industrial rack and shelving Nationwide. Ron and Diana Longo

Efficient storage is at the heart of any successful business that deals with managing any size inventory of supplies and goods. Whether you’re running a

All warehouses have one thing in common: they utilize storage options like rack and shelving material to store their products. These storage materials must be

Warehouses are bustling hubs of activity, with forklifts zipping by, heavy pallets being moved, and employees constantly on the go. While efficiency is key, safety